Welcome! This manual guides you through the Japan Tiger Corporation JKH-G rice cooker. Discover optimal performance and enjoy perfectly cooked rice with these instructions.

Understanding the Model: JKH-G

The JKH-G represents Tiger Corporation’s commitment to innovative rice cooking technology. This model is designed for optimal performance, utilizing a sophisticated heating system and intelligent controls. It’s built to deliver consistently fluffy and flavorful rice. As a modern appliance, the JKH-G incorporates features for versatility, extending beyond basic white rice to include porridge and slow cooking capabilities.

Understanding its core functions—from the inner pot’s construction to the control panel’s intuitive layout—will unlock the full potential of your new Tiger rice cooker. This manual will guide you through each aspect.

Key Features and Benefits

Experience superior rice cooking with the JKH-G! Key features include precise temperature control for perfect texture, and multiple cooking modes for diverse dishes – from fluffy white rice to savory porridge. The ‘Keep Warm’ function ensures your rice stays fresh for hours.

Benefits extend to ease of use; the intuitive control panel simplifies operation. Durable construction guarantees longevity, while the inner pot’s design promotes even heating. Enjoy consistent, delicious results and effortless meal preparation with this versatile appliance.

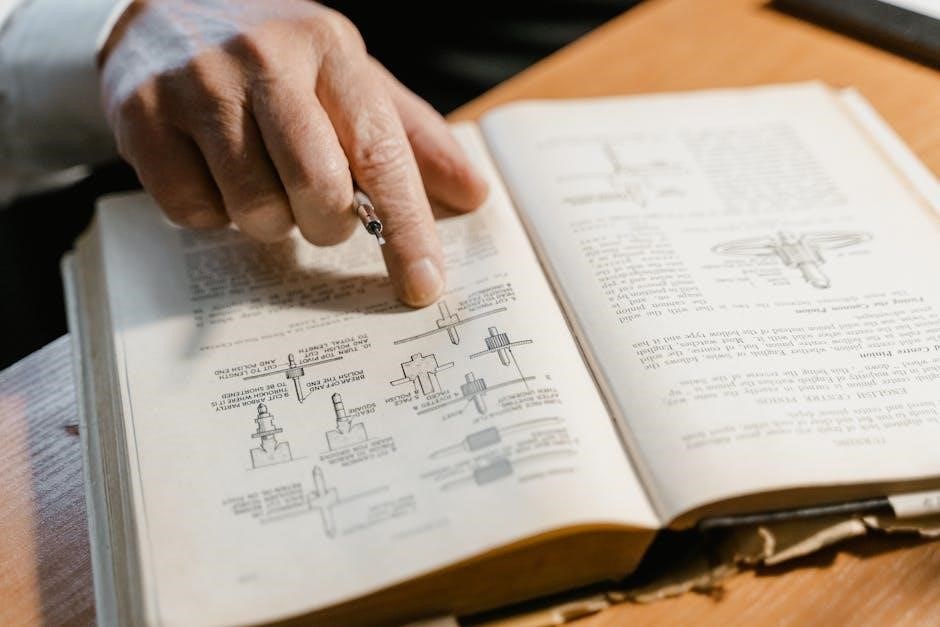

Components of the Rice Cooker

Familiarize yourself with the JKH-G’s parts: inner cooking pot, control panel, steam vent, and condensation collector. These elements work together for optimal performance.

Inner Cooking Pot

The inner cooking pot is crucial for even heat distribution and perfect rice texture. This pot, designed specifically for the JKH-G model, features a durable construction ensuring longevity and consistent cooking results. Regularly inspect the pot for any scratches or damage, as this can affect performance.

Ensure the pot is properly seated within the cooker before each use. Cleaning should be done gently with a soft sponge to avoid damaging the non-stick coating. Avoid abrasive cleaners, as they will compromise the pot’s integrity and cooking efficiency. Proper care extends the lifespan of this vital component.

Control Panel Overview

The control panel of your JKH-G Tiger rice cooker features intuitive buttons for easy operation. You’ll find dedicated buttons for ‘Cook’, ‘Warm’, ‘Porridge’, and ‘Slow Cook’ functions. A digital display clearly shows the current time, cooking mode, and remaining cooking duration.

The ‘Start’ button initiates the selected cooking cycle, while the ‘Cancel’ button allows you to stop the process. Use the ‘Clock’ button to set the current time. Familiarize yourself with each button’s function for a seamless cooking experience. Refer to the detailed function descriptions within this manual.

Steam Vent and Condensation Collector

The steam vent on your Tiger JKH-G rice cooker releases steam during the cooking process; avoid direct contact as it gets very hot. This vent is crucial for achieving perfectly textured rice. Beneath the vent is the condensation collector, a removable tray that gathers excess moisture.

Regularly emptying this collector prevents water overflow and ensures optimal performance. Ensure the collector is properly seated after each use. Cleaning the vent and collector after each cooking cycle prevents buildup and maintains hygiene. Do not obstruct the steam vent during operation.

Getting Started: Initial Setup

Prepare your Tiger JKH-G! Clean the inner pot and cooker thoroughly. Ensure proper placement and connect to a power source for initial operation.

First-Time Use: Cleaning and Preparation

Initial cleaning is crucial! Before your first use, remove all packaging materials. Wash the inner cooking pot with warm, soapy water, ensuring a thorough rinse and complete drying. Wipe the interior of the rice cooker with a damp cloth.

Pay special attention to the steam vent and condensation collector, removing any potential debris. This prevents unwanted odors or flavors from affecting your first batch of rice. A clean cooker ensures optimal performance and longevity. Inspect all components for any shipping damage before proceeding.

Powering On and Basic Operation

Getting started is simple! Plug the rice cooker into a grounded electrical outlet. The power indicator light will illuminate, confirming the connection. Ensure the inner pot is correctly positioned within the cooker. Press the “Start” or “Cook” button to initiate the basic operation.

The cooker will automatically begin the cooking cycle based on the selected mode. Avoid opening the lid during operation to maintain consistent temperature and pressure. Once cooking is complete, the cooker will switch to the “Keep Warm” function automatically.

Setting the Clock

Accurate timekeeping enhances usability! Locate the “Clock” or “Time Set” button on the control panel. Press and hold this button until the hour digits begin to flash. Use the arrow buttons (or corresponding controls) to adjust the hour. Repeat this process to set the minutes.

Confirm your settings by pressing the “Clock” or “Time Set” button again. The clock will now display the current time. Maintaining an accurate clock ensures proper function of timer-based features, like delayed start, if your model supports it.

Cooking Rice: Basic Instructions

Perfect rice is simple! Measure rice and water, select the appropriate cooking mode, and initiate the cycle for fluffy, delicious results every time.

Measuring Rice and Water

Achieving the ideal texture begins with precise measurements. Utilize the provided measuring cup specifically designed for your Tiger rice cooker; standard cups may vary. For white rice, a common ratio is 1 cup of rice to 1.2 cups of water. However, adjust slightly based on your preferred consistency – less water for firmer rice, more for softer.

Brown rice typically requires a higher water ratio, around 1 cup of rice to 1.5 cups of water, and a longer cooking time. Always refer to the inner pot markings as a guide, and experiment to find your perfect rice-to-water balance. Accurate measurement ensures optimal cooking performance.

Selecting the Appropriate Cooking Mode

Your Tiger rice cooker offers various modes for diverse culinary needs. For standard white rice, select the “White Rice” mode. If cooking brown rice, choose the dedicated “Brown Rice” setting for optimal texture and flavor. The “Porridge” mode is ideal for creating creamy, comforting porridge.

Explore the “Slow Cook” function for tender, flavorful meals. Ensure the correct mode is selected before starting the cooking cycle. Incorrect mode selection may result in undercooked or overcooked rice. Refer to the control panel display for clear mode indicators and selection guidance.

Starting the Cooking Cycle

Once the desired cooking mode is selected, press the “Start” button to initiate the cooking cycle. The cooker will automatically adjust temperature and timing based on the chosen setting. Do not open the lid during operation, as this can disrupt the cooking process and release steam.

The control panel will display the remaining cooking time. A signal will sound upon completion. Allow the rice to steam for 10-15 minutes after cooking finishes for optimal texture. Utilize the “Keep Warm” function if immediate serving isn’t possible.

Advanced Cooking Functions

Explore versatile options! Utilize Porridge, Slow Cook, and Keep Warm modes for diverse culinary creations beyond simple rice preparation with your Tiger cooker.

Porridge Cooking Mode

Enjoy creamy, delicious porridge effortlessly! The Tiger rice cooker’s Porridge mode is designed for optimal results with various grains. Begin by adding rice and a generous amount of water – typically a higher ratio than for regular rice. Select the “Porridge” setting on the control panel.

The cooker will automatically adjust cooking time and temperature, preventing sticking and ensuring a smooth consistency. Experiment with different rice types, like glutinous rice, for varied textures. Remember to stir occasionally during the initial stages for even cooking. This mode is perfect for a comforting breakfast or a light, nourishing meal.

Slow Cook Mode

Unlock flavorful, tender meals with the Slow Cook function! This versatile mode allows for extended, low-temperature cooking, perfect for soups, stews, and braised dishes. Add your ingredients – meats, vegetables, and liquids – directly into the inner cooking pot. Select “Slow Cook” on the control panel and choose your desired cooking time.

The Tiger cooker maintains a consistent, gentle heat, developing rich flavors and tenderizing tough cuts of meat. Remember to avoid lifting the lid frequently during cooking to maintain temperature. This mode offers a convenient, hands-off approach to delicious, home-cooked meals.

Keep Warm Function

Enjoy perfectly heated rice for hours with the convenient Keep Warm function! Once the cooking cycle is complete, the rice cooker automatically switches to Keep Warm, maintaining an optimal serving temperature without overcooking. This feature is ideal for busy schedules or when serving guests.

The Keep Warm function can safely hold rice for extended periods, typically up to 12 hours. However, for best quality, it’s recommended to consume the rice within a few hours. Avoid leaving cooked rice on Keep Warm for excessively long durations, as it may affect texture and flavor.

Cleaning and Maintenance

Regular cleaning ensures longevity and optimal performance. Daily wipe the exterior, and thoroughly wash the inner pot and condensation collector after each use.

Daily Cleaning Procedures

After each use, unplug the rice cooker and allow it to cool completely. Remove the inner cooking pot and wash it with warm, soapy water. Rinse thoroughly and dry. Wipe the exterior of the unit with a damp cloth. Pay attention to the control panel, removing any spills or splatters.

Ensure the steam vent and condensation collector are free of debris. Empty the condensation collector and wash it with warm, soapy water. Reassemble all parts before storing. Avoid abrasive cleaners, as they may damage the surfaces. Consistent daily cleaning maintains hygiene and extends the lifespan of your Tiger rice cooker.

Deep Cleaning Instructions

Monthly, perform a deep clean. Unplug and cool the cooker. Remove all detachable parts – pot, lid, steam vent, and collector. Wash these in warm, soapy water. For stubborn residue in the pot, simmer a solution of water and vinegar for 5-10 minutes, then scrub gently.

Wipe the cooker’s interior with a damp cloth. Inspect the heating plate for buildup; carefully remove with a soft brush. Ensure all parts are completely dry before reassembling. Avoid immersing the main unit in water. Deep cleaning ensures optimal performance and prevents odors, maintaining your Tiger rice cooker’s longevity.

Troubleshooting Common Issues

If the cooker won’t start, check the power cord and outlet. Ensure the inner pot is correctly positioned. For undercooked rice, increase the water slightly or select a longer cooking mode. Overcooked rice? Reduce water or choose a shorter cycle.

If error codes appear, consult the manual’s error code section. A faulty steam vent or condensation collector can cause issues; ensure they are clean and properly installed. Regular maintenance prevents most problems. If issues persist, contact Tiger customer support for assistance.

Safety Precautions

Always unplug the cooker before cleaning. Avoid water entering the electrical components. Handle the hot inner pot with care to prevent burns and damage.

Electrical Safety Guidelines

Ensure your outlet voltage matches the cooker’s specifications. Never operate with a damaged cord or plug; replace immediately. Avoid using extension cords if possible, and if necessary, use a heavy-duty cord rated for the appliance’s wattage. Do not immerse the cooker base, cord, or plug in water or other liquids.

Always unplug the cooker when not in use and before cleaning. Never pull the cord to disconnect; grasp the plug instead. Keep the cord away from hot surfaces. If the cooker malfunctions, discontinue use and contact customer support for assistance – do not attempt repairs yourself. Proper grounding is essential for safety.

Proper Usage and Handling

Always place the rice cooker on a stable, heat-resistant surface away from flammable materials. Use oven mitts when handling the hot inner cooking pot and steam vent. Avoid touching the heating plate directly. Do not operate the cooker without the inner pot properly in place.

Never attempt to force the lid open during operation. Allow the cooker to cool completely before cleaning or storing. Do not use abrasive cleaners or scouring pads, as they can damage the non-stick coating. Handle the unit with care to prevent dents or damage to the exterior.

Avoiding Damage to the Unit

Protect your Tiger rice cooker by preventing water from entering the main body. Do not immerse the unit in water or other liquids. Avoid dropping the cooker or subjecting it to strong impacts. Ensure the power cord is not bent, twisted, or damaged in any way.

Refrain from using metal utensils inside the cooking pot, as they can scratch the non-stick surface. Do not attempt to disassemble or repair the cooker yourself; contact customer support for assistance. Proper care extends the lifespan and maintains optimal performance.

Troubleshooting

Resolve common issues! Check for error codes, undercooked or overcooked rice, and ensure proper operation. Refer to this section for quick solutions and guidance.

Rice is Under cooked

If your rice remains undercooked, first verify you’ve used the correct rice-to-water ratio as detailed in the ‘Cooking Rice’ section. Ensure the inner cooking pot is seated correctly and the lid is sealing properly. A faulty seal can prevent sufficient steam buildup.

Also, confirm you selected the appropriate cooking mode for the rice type – white, brown, or other. Try increasing the cooking time slightly or adding a small amount of water for the next cycle. If the issue persists, contact customer support for assistance, referencing the model JKH-G.

Rice is Overcooked

If your rice is consistently overcooked, double-check the water measurement. Reducing the water slightly in subsequent cooking cycles can resolve this. Ensure you are not using a cooking mode intended for stickier rice varieties if you prefer a firmer texture. Verify the inner pot is clean and free of residue, as buildup can affect cooking temperature.

Also, confirm the steam vent and condensation collector are clear of obstructions. If overcooking continues with the JKH-G model, contact customer support for further troubleshooting guidance.

Error Codes and Their Meanings

The JKH-G rice cooker utilizes error codes to indicate specific issues. “E1” typically signals a sensor malfunction, requiring service. “E2” suggests a heating element problem; discontinue use immediately. “E3” indicates a lid closure issue – ensure the lid is securely fastened during operation. If an unrecognized error code appears, power cycle the unit.

Consult the full troubleshooting section or contact Tiger customer support, providing the specific error code for efficient assistance. Ignoring error codes may lead to further damage.

Recipes for Your Tiger Rice Cooker

Explore culinary possibilities! From simple white rice to steamed vegetables and flavorful porridge, unlock delicious recipes tailored for your Tiger JKH-G cooker.

Simple White Rice Recipe

Yields: Approximately 4 servings

Prep time: 5 minutes

Cook time: 30-40 minutes

Ingredients: 2 cups Japanese short-grain rice, 2.5 cups water.

Instructions: Thoroughly rinse the rice under cold water until the water runs clear. This removes excess starch for fluffier results. Place the rinsed rice and water into the inner cooking pot of your Tiger JKH-G rice cooker. Secure the lid and select the “White Rice” cooking mode. Press start to begin the cooking cycle. Once complete, let the rice steam for 10 minutes before fluffing with a rice paddle. Enjoy!

Brown Rice Cooking Guide

Yields: Approximately 4 servings

Prep time: 5 minutes

Cook time: 45-60 minutes

Ingredients: 2 cups brown rice, 3 cups water.

Instructions: Rinse the brown rice under cold water. Place the rinsed rice and water into the Tiger JKH-G’s inner pot. Select the “Brown Rice” cooking mode on your rice cooker’s control panel. Press the start button to initiate the cooking process. After the cycle finishes, allow the rice to steam, covered, for 10-15 minutes. Fluff gently with a rice paddle before serving. Adjust water slightly for desired texture.

Steamed Vegetable Recipe

Yields: Approximately 2-3 servings

Prep time: 10 minutes

Cook time: 15-20 minutes

Ingredients: 1 cup broccoli florets, ½ cup sliced carrots, ½ cup snap peas, 2 tablespoons water.

Instructions: Place vegetables in a heat-safe steaming basket. Add 2 tablespoons of water to the inner pot of your Tiger JKH-G rice cooker. Position the steaming basket inside. Select the “Steam” function (or use the ‘Slow Cook’ mode on low). Start the cycle. Check for desired tenderness after 15 minutes. Season with salt and pepper before serving.

Warranty Information

Coverage: Your Tiger JKH-G rice cooker is covered by a one-year limited warranty against manufacturing defects. Contact customer support for details.

Coverage Details

What’s Covered: This warranty protects against defects in materials and workmanship under normal household use for one year from the date of original purchase. It includes malfunctions arising from typical operation as described in this instruction manual.

What’s Not Covered: Damage resulting from misuse, abuse, accidents, unauthorized repairs, or alterations are excluded. Normal wear and tear, commercial use, and acts of God are also not covered. This warranty is non-transferable and applies only to the original purchaser.

Claim Process: To initiate a warranty claim, contact Tiger customer support with proof of purchase and a detailed description of the issue.

Contacting Customer Support

For Assistance: Should you encounter any issues or have questions regarding your Tiger JKH-G rice cooker, our dedicated customer support team is here to help. We strive to provide prompt and efficient assistance to ensure your satisfaction.

Contact Methods: You can reach us via phone at 1-800-TIGER-USA (1-800-844-3787) during business hours, Monday-Friday, 9 AM to 5 PM EST. Alternatively, email us at support@tigercorporation.com. Please include your model number and a detailed description of your concern.

Website Resources: Visit our website at www.tigercorporation.com for FAQs, troubleshooting tips, and downloadable resources.